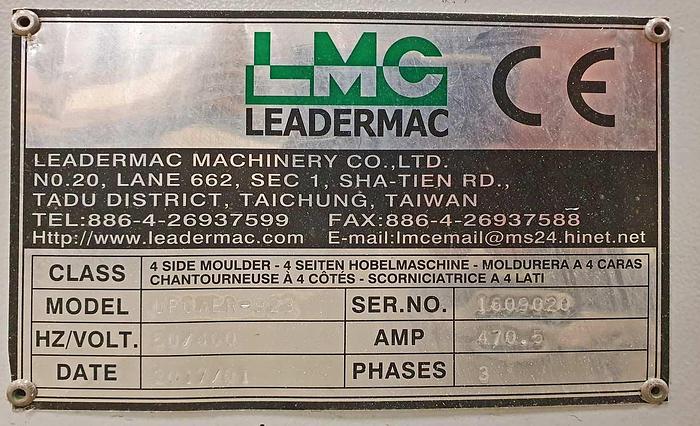

2017 Leadermac / Kentwood Planer / Moulder LEADERMAC Upower LMC-923 ( 9 spindle)

Description

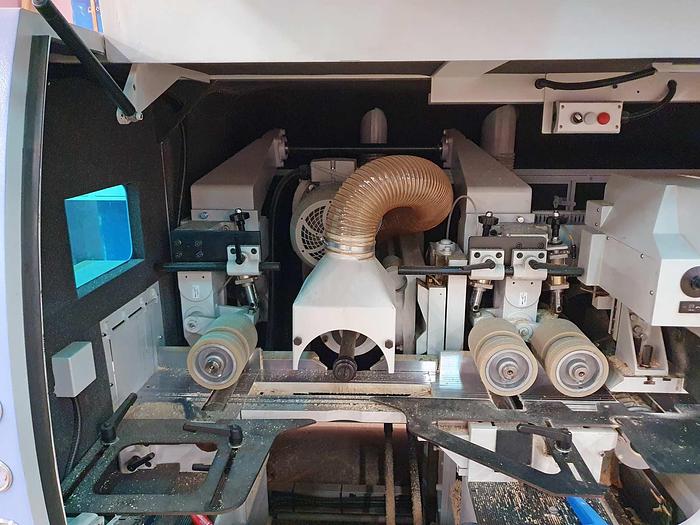

Planer / Moulder LEADERMAC Upower LMC-923 ( 9 spindle)

( 4 SIDE MOULDER "KENTWOOD M809X/A/U" )

year 2017

manufacture Leadermac / Kentwood

9TH SPINDLE WITH UNIVERSAL HEAD 15HP

TECHNICAL DATA:

MIN.WORKING WIDTH : 15 mm

MAX.WORKING WIDTH : 230 mm (WITH A TOOL CUTTING CIRCLE OF 163mm)

MIN.WORKING THICKNESS : 10 mm

MAX.WORKING THICKNESS : 150 mm (WITH A TOOL CUTTING CIRCLE OF 163mm)

**MIN. WORKING LENGTH: 800mm (ONE PIECE)

**MIN. WORKING LENGTH: 350mm (ONE PIECE AND ONE PIECE)

1ST BOTTOM SPINDLE - 25HP, ALLOWABLE CUTTING CIRCLE 125 - 180 mm

2ND RIGHT SPINDLE - 20HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

3RD LEFT SPINDLE - 20HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

4TH RIGHT SPINDLE - 20HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

5TH LEFT SPINDLE - 20HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

6TH TOP SPINDLE - 30HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

7TH TOP SPINDLE - 30HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

8TH BOTTOM SPINDLE - 30HP, ALLOWABLE CUTTING CIRCLE 80 - 203 mm (FOR HSK CUTTER)

9TH UNIVERSAL SPINDLE- 15HP, ALLOWABLE CUTTING CIRCLE 125 - 200 mm

UP & DOWN MOTOR : 3/4 HPx1

FEED MOTOR: 7.5 HPx1/INVERTER 1ST, 9TH SPINDLE DIAMETER : 40mm

2ND - 8TH SPINDLE: HSK-80F

1ST, 9TH SPINDLE R.P.M. : 6,000 - 8,000 R.P.M.

2ND - 8TH HSK-80F SPINDLE R.P.M.: 8,000 - 10,000 R.P.M.

FEED SPEED, INF INITELY VARIABLE : 6 -30 M/min

STANDARD FEATURES:

1) SOUND & SAFETY ENCLOSURE.

- THE ENTIRE MACHINE IS COVERED TO REDUCE NOISE & SAFETY WORKING ENVIREMENT.

2) HARDEN CHROMED FOR ENTIRE FEEDING TABLE.

-0.3 mm HARDEN CHROMED ON ITS SURFACE TO LAST ITS SERVING LIFE_

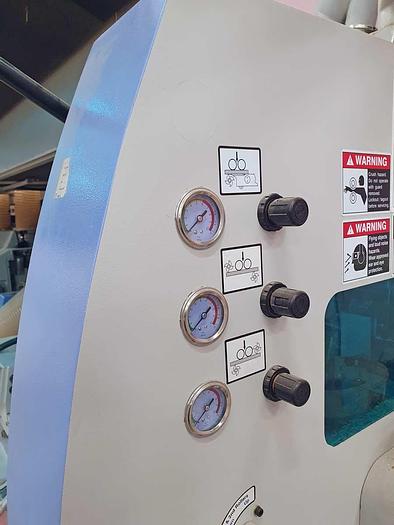

3) 3 STAGE PRESSURE SETTING OF FEED ROLLER_

-PNEUMATIC ROLLER PRESSURE COMPENSATES FOR LARGE VARIANCES IN WORK PIECE THICKNESS. THE MAX. AIR PRESSURE SETTING IS 6 BAR.

4) AUTO. OIL LUBRICATION FOR FEEDING TABLE.

-TO SUPPLY OIL ON THE 2 POINTS OF FEEDING TABLE WITH TIMER CONTROL.

5) 1.8 METER INFEED TABLE.

-ADJUSTMENT RANGE FOR INFEED TABLE & EDGE-JOINTING FENCE IS 10 mm.

6) STEEL BODY_

7) POWER DRIVEN UPPER ROLLER & 7 UNITS OF BOTTOM ROLLER ARE EQUIPED WITH POWER DRIVEN ROLLERON THE FEED TABLE.

-BOTH UPPER & BOTTOM FEED DRIVEN BY CARDEN UNIVERSAL JOINT DRIVE WITH NO CHAINS PREVEND STOCK-FREE, MORE ROBUST, LOW MAINTAINANCE, LONGER SERVICE LIFE & MORE ACCURATE.

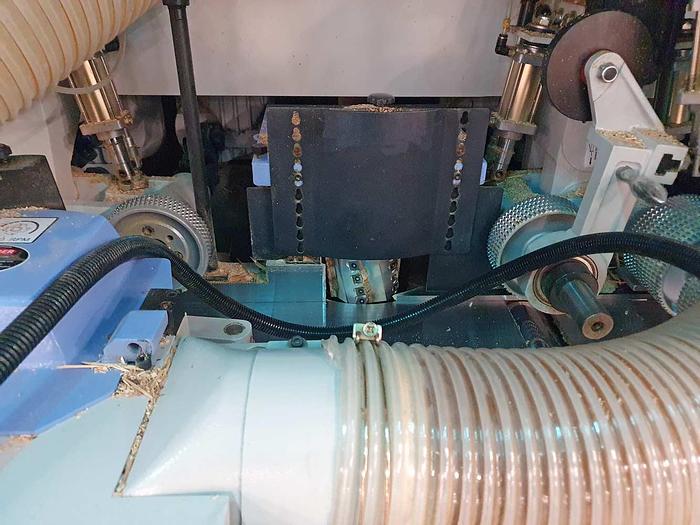

8) HIGH PRECISION SPINDLE WITH THE HIGH SPEED BEARING.

9) DOCUMENTATION_

-MAINTENANCE MANUAL OPERATION MANUAL, ELECTRICAL DIAGRAMS & PARTS LIST_

10) TOOL BOX_

11) ADJUSTMENT RANGE OF VERTICAL SPINDLE (AXIAL) MAX_ 80mm.

12) ADJUSTMENT RANGE OF HORIZONTAL SPINDLE (AXIAL) MAX 40mm.

13) 2ND - 8TH SPINDLE TO ALLOW MAX_ CUTTING CIRCLE WITH 30mm DEPTH OF PROFILE.

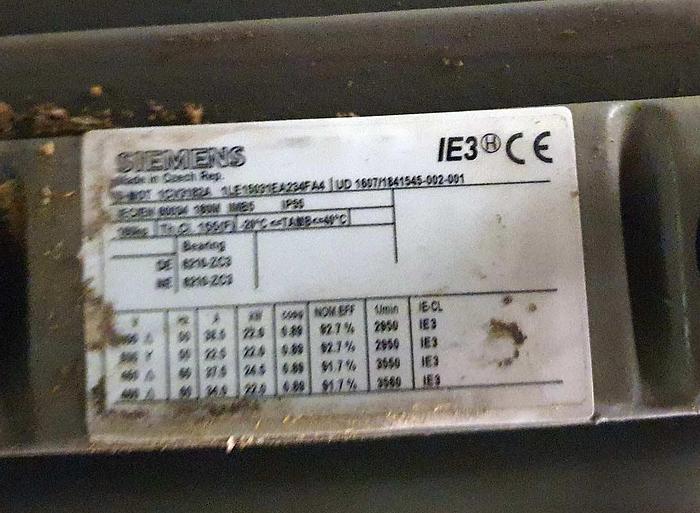

14) SIEMENS MOTOR WITHOUT MECHANICAL BRAKE.

15) SIEMENS ELECTRICAL COMPONENTS (BUT THE BUTTONS USE KLOCKNER MOELLER ELECTRICAL COMPONENTS).

16) 2 PCE FEED WHEEL SPACERS FOR WI DE STOCK HOLDOWN. (#168465)

17) INFEED FENCE WITH REFERENCE ENGRAVING.

18) 1ST SPINDLE WITH REPLACEABLE CARBIDE REFERENCE TOOL (OPTION) ONLY, AND OTHER SPINDLES WITHOUT CUTTER TOOLS.

19) TOP SPINDLE WITH NEW DESIGN DUST HOOD WITH 3.5" LCD DISPLAY FOR PRESSURE SHOE AND CUTTING CIRCLE. (R#1)

20) LEFT SPINDLE WITH 3.5" LCD DISPLAY FOR PRESSURE ELEMENTS AND CUTTING CIRCLE_

21) TO SUPPLY "CE" STANDARD FOR ELECTRICAL COMPONENTS & MACHINES.

Technica describtion under subject of correction

Specifications

| Manufacturer | Leadermac / Kentwood |

| Model | Planer / Moulder LEADERMAC Upower LMC-923 ( 9 spindle) |

| Year | 2017 |

| Condition | Used |