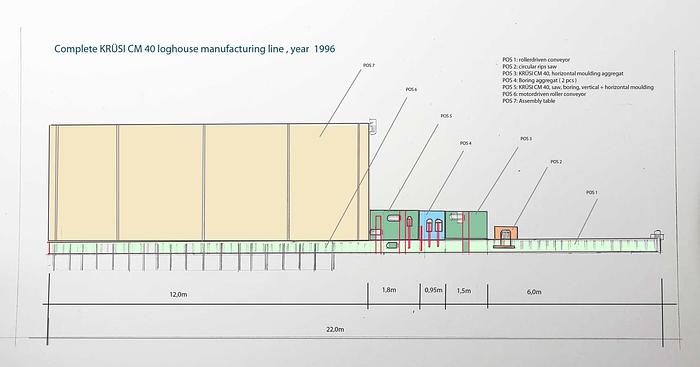

KRÜSI Log House Production Line Type CM 40

Description

KRÜSI Chalet Building Machine / Log House Production Line Type CM 40

Consisting of:

POS 1:

Motor-driven roller conveyor

Working width 400mm, infinitely variable feed speed

2,0 kw feed motor

length 6000mm

POS 2:

Longitudinal saw

Diameter saw blade 400mm

The pneumatic feed of saw depth

Main motor 4,0 kW

Max. saw blade saw blade 400mm

POS 3:

KRÜSI chalet building machine/log house finishing machine type CM 40.

Year of manufacture approx. 1985

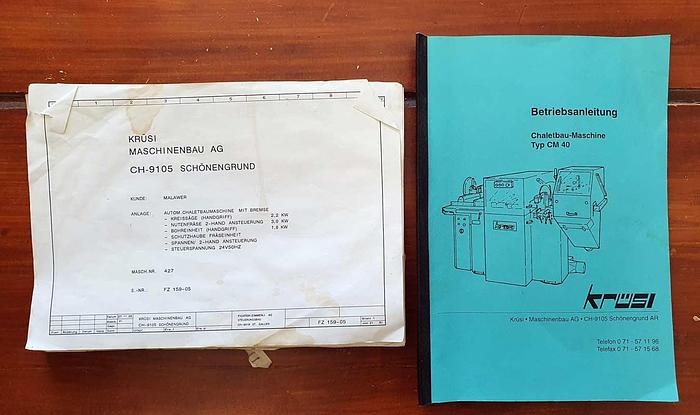

Manufacturer:

Krüsi Maschinenbau AG CH-9105 Schönengrund AR

Horizontal milling unit

cutter- Ø 180mm

cutter width max.130mm

from cutter width of 60 mm use only aluminium alloy cutters with reversible cutting edges

1 motor with manual feed

kW 2,2

Rapid traverse and work feed infinitely adjustable

POS 4:

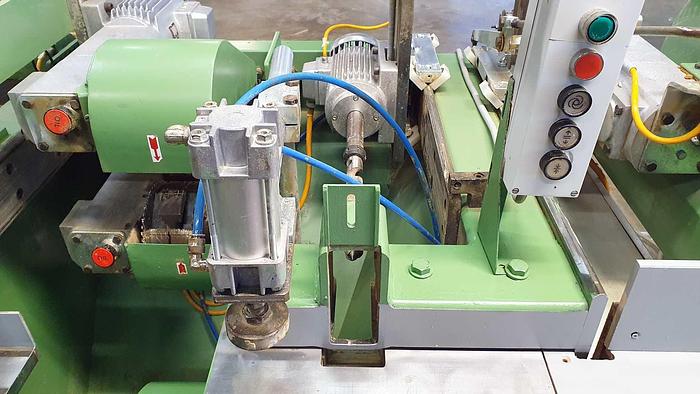

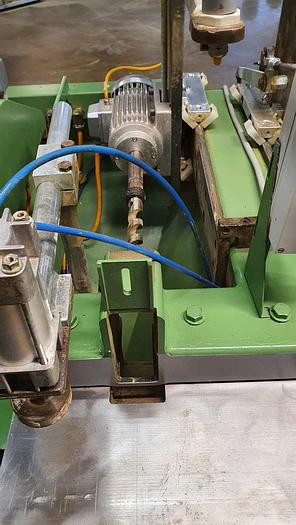

Drilling unit:

Hydropneumatic feed

Spindle adjustment with analogue dimension display

Drilling unit

2 drill bits collet chuck ER 25

Clamping Ø max. mm 16

Drill Ø max. mm 32

Motor min'1 1450, kW 1,8

POS 5:

KKRÜSI RÜSI Chalet Building Machine / Log House Finishing Machine Type CM 40

Machine-No.431

Year of manufacture 1996

Manufacturer:

Krüsi Maschinenbau AG CH-9105 Schönengrund AR

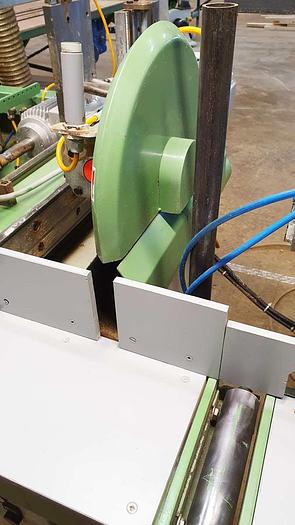

Sawing unit:

Manual feed

Spindle adjustment with analogue dimension display

CM milling unit:

Hydropneumatic feed

Spindle adjustment with digital display

Drilling unit:

Manual feed

Spindle adjustment with analogue dimension display

Face milling unit

Hydro-pneumatic feed

Spindle adjustment with digital dimension display

POS 6:

Motor-driven roller conveyor

Working width 400mm, infinitely variable feed speed

2,0 kW feed motor

Length 12000mm

9 pcs. stop flaps, adjustable, pneumatically controllable

10 pieces side-shift for material transfer

POS 7:

Assembly table 4.400mm x 12.000mm

Manufacturer: Sweden

Year of construction approx. 1985

Assembly table for further processing of the finished log house planks.

4 chain hoists for cross transport

Gear motor with 4,0 kW

Further information about POS 5:

KRÜSI Chalet Building Machine / Log House Finishing Machine Type CM 40

Machine-No.431

Year of manufacture 1996

Manufacturer:

Krüsi Maschinenbau AG CH-9105 Schönengrund AR

Sawing unit:

Manual feed

Spindle adjustment with analogue dimension display

CM milling unit:

Hydropneumatic feed

Spindle adjustment with digital display

Drilling unit:

Manual feed

Spindle adjustment with analogue dimension display

Face milling unit

Hydro-pneumatic feed

Spindle adjustment with digital dimension display

Technical data

Workpiece

Cutting height max. 200nn

Cutting width max. 250mm

Working table height 900mm

Saw unit

Saw blade-Ø max. / bore-o 400 / 30 mmm

Carbide tipped with chip limiter (synchronous operation)

Adjustable riving knife

Motor speed min 1 / 2900

Power kW 2,2

Horizontal/vertical milling unit

Horizontal milling unit

Cutter Ø 180mm

Cutter width max.130mm

from cutter width of 60 mm use only aluminium alloy cutters with reversible cutting edges

2 motors hydro-pneumatic feed

kW each 2,2

Hydropneumatic feed

Rapid traverse and working feed infinitely variable

Drilling unit

Drill holder Collet ER 25

Clamping Ø max. mm 16

Drill Ø max. mm 32

Motor min'1 1450, kW 1,8

Face milling unit

Fraser- Ø max. mm 230

Cutter width max. mm60

Motor min1 / 2900, kW 3,0

2 V-belts SPZ 9,5x1000 La

Pneumatic

On-site operating pressure min/max MPa (bar) 0.7/1 (7/10)

Air consumption Nm3/h 8

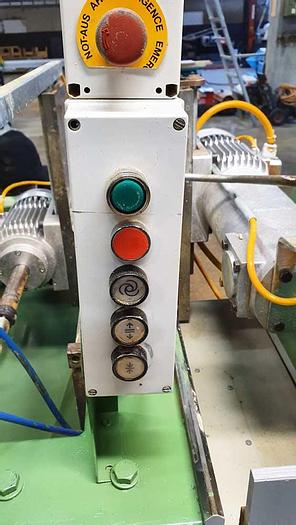

Electrical system

Operating voltage V / Hz 380, 50

Nominal power kW 8.8 -15.8 depending on the version

On-site back-up fuse A 3 x 25 slow-blow

Simultaneously in use max. kW 4.4

Dimensions

Machine width 1300-2400mm depending on model

Machine depth 1600mm

Total height, protective bonnet at bottom 1600mm

Total height, protective bonnet up 2200mm

Extraction connection- Ø underbody extraction

Saw unit

Horizontal/vertical milling unit

Drilling unit

Face milling unit

Pit extraction ( see requirements for the installation site )

Connection pipe - Ø 200

Weight approx. 800- 1300kg depending on model

Noise information

Workplace-related emission value

according to DIN 45635

dB(A) dB(A)

Idling

Machining

Sound power level

Idling dB(A)

Machining dB(A)

(Due to measurement and manufacturing tolerances, deviations of up to 3 dB(A) are possible.

Dust emission

Measuring point Measuring location/activity

Machining of spruce beams

On the left side in front of the machine

On the right side in front of the machine

Sampling time 45min

Sampling time 45min

Conc. Total dust in mg/m3

<0,18

<0,18

The maximum workplace concentration (MAK) for spruce dust is 0.2 mg/m3 (total dust).

MAK = Maximum workplace concentration of a substance in the air, at exposure during 8 hours daily.

5 Description of the machine

5.1 Principle of operation

Processing of timber for chalet construction. The beams can be processed in one pass, e.g.

- cutting to length (if equipped with a saw unit)

- horizontal and vertical milling of the necks in one set-up

- drilling (if equipped with a drilling unit)

- milling of the face grooves (if equipped with a face groove milling unit)

5.2 Standard design

Robust construction in welded design.

Machine (horizontal and vertical milling unit) with 4 special milling motors,

with hardened and ground guides for the highest machining accuracy.

Carriage guided by dust-protected and preloaded ball-bearing rollers.

Working range up to 200 x 250 mm. Completely ready for operation, with contactor control,

motors protected by thermal relays.

Electrical equipment for voltage 380 V, 50 Hz, with protective bonnets,

central connection for on-site chip extraction, with 2 eccentric clamps,

without milling tool (folder).

With hydropneumatic horizontal and vertical feed electrically controlled,

together with the start-up of the milling motors.

Rapid traverse and feed are infinitely adjustable. Completely wired and installed, including air maintenance unit.

Stains with a thickness of more than 14 cm must be processed in two tensions.

Such patches have to be re-milled by the amount of the extra thickness.

Machine guards over the moving parts with gas spring weight compensation.

5.3 Standard accessories

Mouth spanner SW 41 for milling tool Toggle hexagon socket spanner SW 10 Ring spanner SW 36

Slot spanner for ER 25 (if equipped with drilling unit)

Control cabinet key Electrical switch cover in control cabinet Operating instructions for CM 40

5.4 Options

Sawing unit

Sawing unit (3) with manual feed mounted on left-hand machine stand with

- Protective bonnet, splitting wedge holder and splitting wedge

- Suction socket and additional table

- Spring return and locking pawl

- Circular saw blade 0 400 / 30 mm

CM-horizontal/vertical milling unit (4/5-fig.10+)

- with the automatic work cycle

- Sequence control for automatic cycle Add-on built into the control cabinet

Drilling unit and face milling unit

Drilling unit (6) and face milling unit (7) mounted on the right-hand machine stand with

- manually operated drilling unit

- manually operated milling unit with vertical axis 2 Milling of face grooves

Hydropneumatic feed with

- saw unit

- Drilling unit

- Face groove milling unit

Spindle adjustment with digital display for:

Sage unit

- Horizontal/vertical milling unit

- Drilling unit

- Face groove milling unit

Technical specifications are subject to change!

Specifications

| Manufacturer | Krüsi Switzerland |

| Model | Joinery system Krüsi CM-40 |

| Year | 1996 |

| Condition | Used |

| Stock Number | KRÜSI Chalet Building Machine / Log House Production Line Type CM 40 |